The experts at Denton Drapes share the details! Here's what they have to say:

"We are a high quality trade and retail workroom so attention to detail is very important to our customers and to ourselves. When making curtains we specialise in pleating to the design of the fabric which makes a tremendous difference to the look of the final product.

Not all workrooms pleat to the design of the fabric as it requires more fullness than the normal amount, usually three times fullness. This increases the cost of the finished product but when done correctly it is beautiful to look at. Many curtain workrooms are more mechanised than ours so their pleating relies solely on measurement without the experienced eye of skilled curtain makers such as those we have in the Denton Drapes team.

You will see that every single fold of fabric within in the curtain falls in exactly the same part of the pattern. This is particularly important when using a fabric like a stripe.

If you do not pleat to the design of the fabric or stripe the result will be a very haphazard appearance.

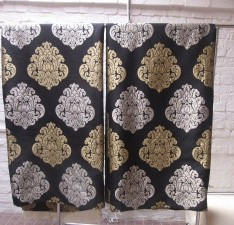

It is usually very obvious to us when our clients are making their fabric selection if we will need to pleat to the pattern. For example, a large flower or motif repeated across the width is a typical design requiring this practise.

Sometimes it is not always immediately obvious when looking at a fabric that pleating to the design is required. A few months ago we had exactly this situation with a beautiful all over embroidered linen from Harlequin fabrics. Even when the fabric was rolled out onto the table for checking, the design of the embroidery fooled my eyes.

It wasn’t until the curtain was complete and was hung ready for dressing that the mistake became obvious. As you can see, the colour in the embroidery is green and blue. Once the curtain was hung half of the curtain appeared predominantly with blue flowers, they then faded away for the next few widths and the other half of the curtain was green foliage. This was because we had pleated the heading to the required measurement only. The customer would also have seen that the curtain didn’t look quite right but probably wouldn’t have known why.

There was only one option. We removed the pleats and reworked the heading calculation according to the design of the fabric so that every pleat fell onto the same part of the pattern. We needed to reduce the width of the first and last panels so that our pleats fell on the same part of each flower across the curtain. It was quite a lot of work but well worth it for the finished look of the curtain.

The pleating arrangement is even more evident once the curtain has been dressed and bandaged.

In this case you can see that every other pleat is on the same colour of flower."

Comments